When a mid-sized fashion brand came to us with a challenge, they needed a practical solution, not just a quick fix and they had a 3 week time frame. They were switching to a new third-party logistics (3PL) provider to improve inventory management and fulfillment, but integrating their existing NetSuite system with the new warehouse management system (WMS) wasn’t going to be straightforward.

Making the Switch Without Disrupting Operations

Moving to a new 3PL is never as simple as flipping a switch. The company needed real-time synchronization between NetSuite and the new 3PL’s custom WMS (ALG) to avoid delays, inventory mismatches, and order processing hiccups. At the same time, they couldn’t afford to slow down operations during the transition. The key concerns were:

- Keeping inventory data accurate across both systems.

- Automating order processing and fulfillment.

- Providing full visibility into warehouse activities.

- Customizing data flows to fit their specific needs.

Without the right integration, the company risked fulfillment delays, inventory errors, and a frustrating customer experience.

Our Solution: A Smooth and Reliable Integration with Celigo

To ensure a seamless connection between NetSuite and the new WMS, we leveraged Celigo, a powerful integration platform, to automate workflows and facilitate real-time data exchange. Here’s how we did it:

holds to fit your sales strategy.

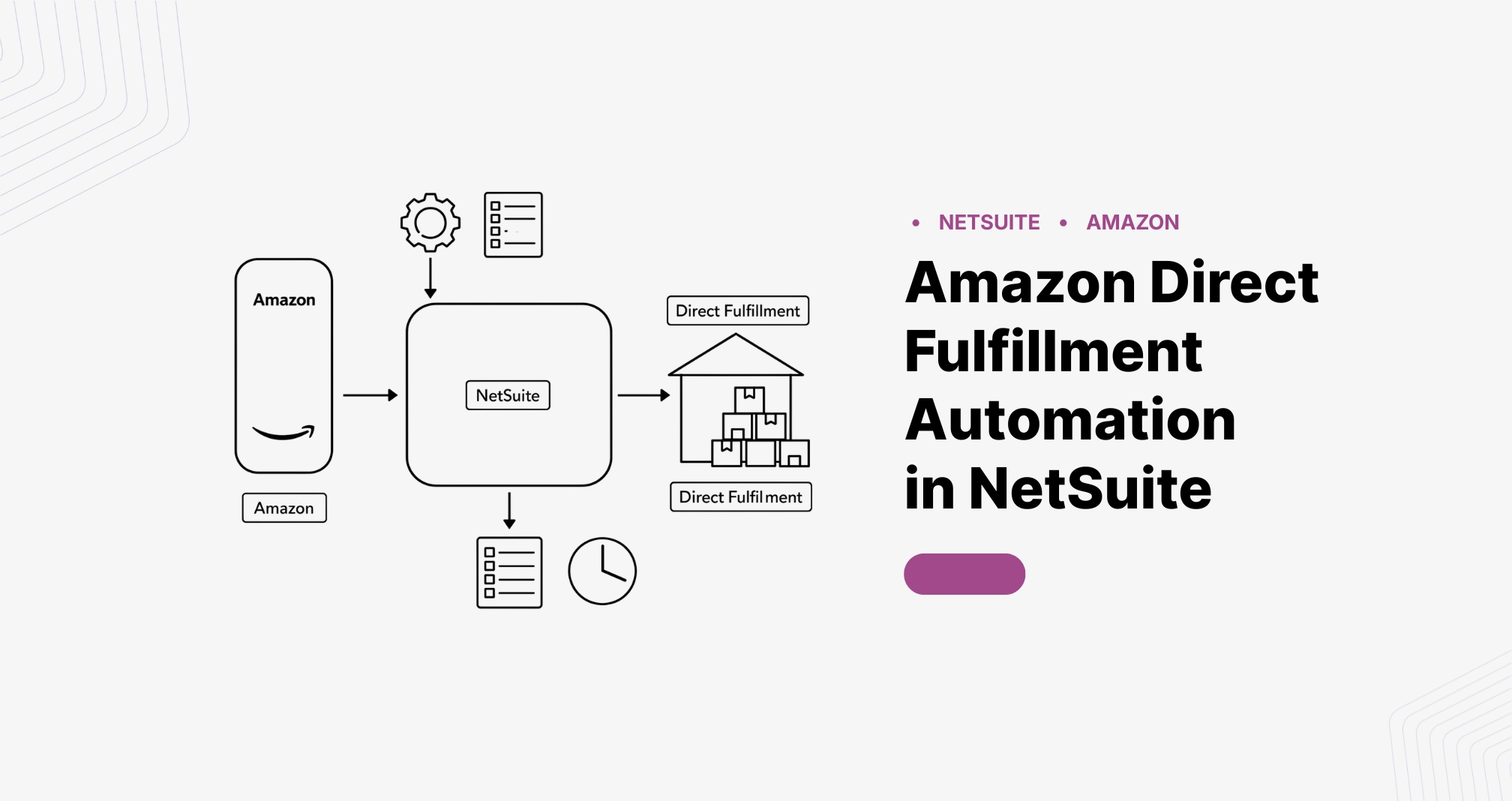

1. Custom API Development for Direct Communication

Since NetSuite and the new WMS weren’t natively compatible, we developed a custom API, integrated through Celigo, to bridge the gap. This allowed for:

- Orders to be automatically sent from NetSuite to the warehouse for processing.

- Instant updates on inventory levels, preventing overselling and stock discrepancies.

- Real-time tracking information to be pushed back into NetSuite, keeping customers and internal teams informed.

Automating these processes eliminated the need for manual data entry and reduced the chances of human error.

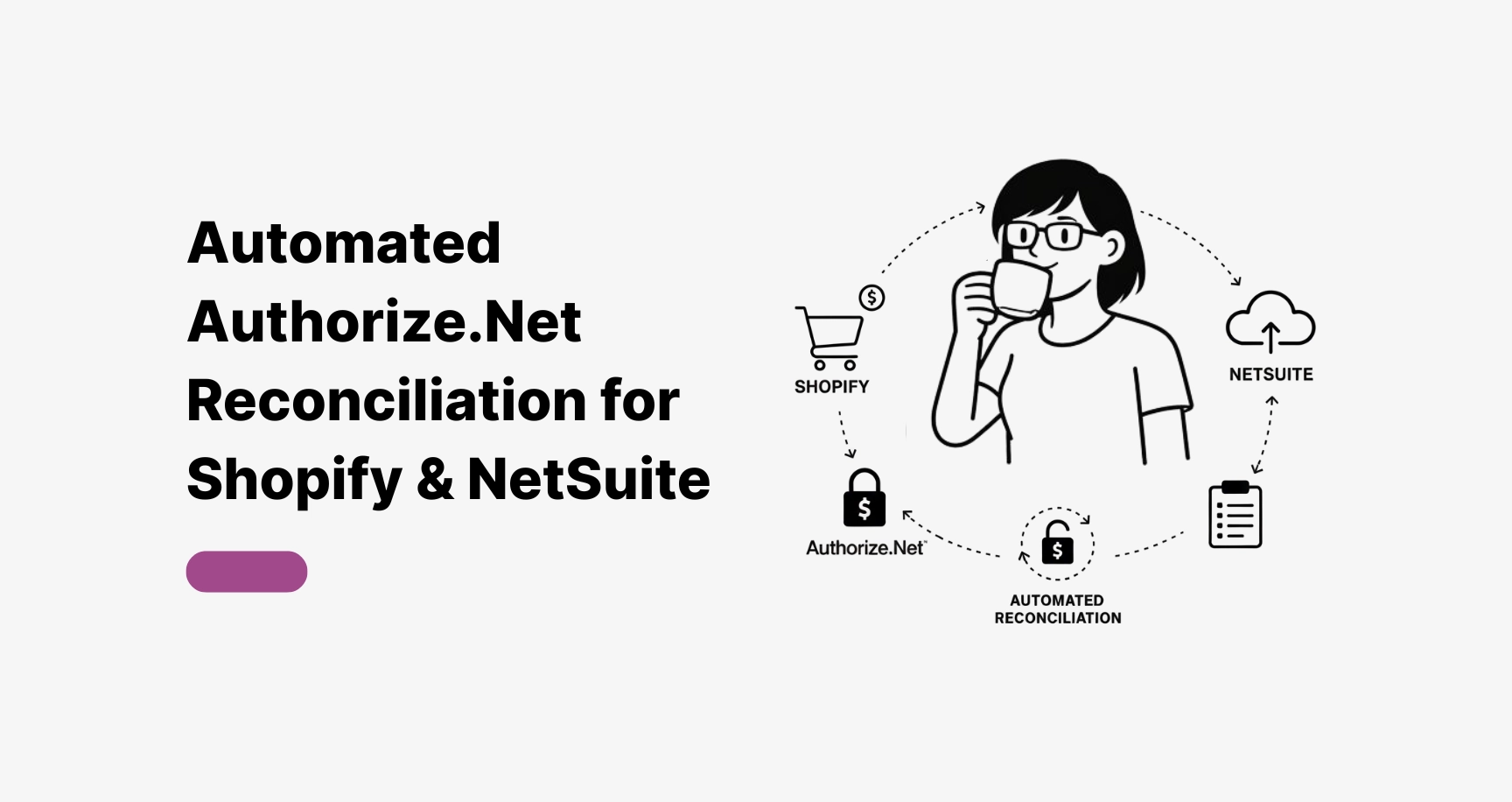

2. Real-Time Inventory Synchronization

Inventory inaccuracies can lead to big headaches—stockouts, delays, and unhappy customers. Our integration ensured that NetSuite and the WMS always reflected the same stock levels. This meant:

- Fewer stock discrepancies.

- A reduced risk of overselling.

- Better forecasting and replenishment planning.

With up-to-date inventory visibility, the company could make smarter decisions and keep operations running smoothly.

3. Faster Order Processing

Fashion brands often deal with a high volume of orders, especially during seasonal sales. To keep up with demand, we automated the entire order lifecycle using Celigo:

- Orders placed in NetSuite were instantly pushed to the WMS for fulfillment.

- The system automatically updated order statuses, so customer service teams always had the latest info.

- Shipping labels and tracking numbers were generated without manual input, speeding up the packing and shipping process.

This automation cut down order processing times significantly and improved overall efficiency.

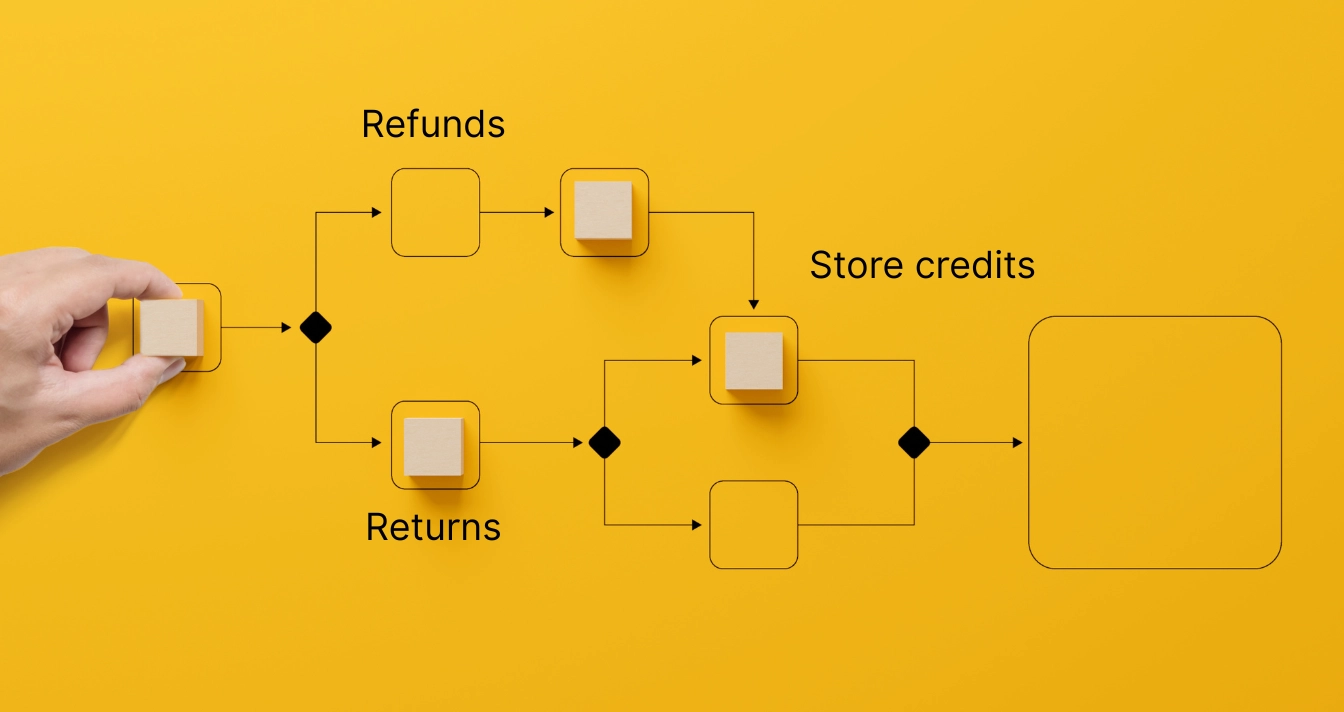

4. Custom Workflows for Business-Specific Needs

Every business has its own way of handling orders, returns, and special requests. Instead of forcing the company to change its processes, we tailored the integration to fit their workflow. This included:

- Rules for handling returns and exchanges smoothly.

- Automated split shipments for multi-item orders.

- Special handling instructions for high-value or fragile items.

By customizing the integration to match their needs, we ensured the transition to the new 3PL didn’t disrupt their existing processes.

5. Thorough Testing and a Smooth Go-Live

A WMS integration is only successful if it works under real-world conditions. Before going live, we ran extensive tests, including:

- End-to-end order flow testing.

- Stress tests to simulate peak demand.

- Hands-on training for warehouse and customer service teams.

When launch day came, the company experienced minimal disruptions, and operations continued as planned.

Faster, More Accurate Fulfillment

After implementing the integration, the company saw immediate improvements:

- Order processing times dropped by 30%, leading to faster deliveries.

- Inventory accuracy hit 99%, reducing stock-related issues.

- Warehouse operations became more efficient, cutting down labor costs.

- Customers received their orders faster, improving satisfaction and repeat purchases.

Why This Matters for Fashion & Apparel Brands

Fast shipping and accurate inventory aren’t just nice to have—they’re essential in today’s retail landscape. Shoppers expect quick, hassle-free fulfillment, and brands that can’t deliver risk losing customers to competitors. With a solid 3PL integration, businesses can:

- Scale their operations without bottlenecks.

- Handle seasonal demand surges effortlessly.

- Maintain high levels of customer trust and satisfaction.

What’s Next: Future-Proofing for Growth

While this integration solved immediate challenges, we built it with scalability in mind. As the company grows, the system can be adapted to support additional warehouses, new shipping carriers, and evolving business needs.

Final Thoughts

Switching to a new 3PL can be a complex process, but with the right strategy, it doesn’t have to be a painful one. By leveraging Celigo for integration, we helped this fashion brand streamline its warehouse operations, improve efficiency, and enhance the customer experience.

If you’re dealing with similar challenges, we can help you build a solution that fits your business and keeps your operations running smoothly. Let’s talk about how we can make your logistics work better for you.