With the increasing complexity of global trade, e-commerce businesses are in need of solutions that will support their ambitions to grow and help them in optimizing supply chain management. And while CRMs and ERPs can indeed do that, they are at their strongest when integrated together into one powerful system. This is where Celigo steps in – a leading integration platform designed to seamlessly connect all vital e-commerce systems like Shopify, Amazon, NetSuite and many others.

In this article, our team will leverage many years of experience of working with Celigo to explore how it can revolutionize your e-commerce operations. We will break down the fundamentals of supply chain optimization solutions as well as highlight Celigo’s capabilities and discuss how it will enable your long-term success.

What Is Supply Chain Optimization?

Supply chain optimization is fine-tuning your entire supply process to make it as smooth and cost-effective as possible. More precisely, it means always having the right amount of inventory at the right time, being able to predict customer demand and quickly responding to changes in the market.

This is typically achieved by getting real-time visibility into your supply chain – one way to do it is to connect your e-commerce system (Shopify, Amazon, etc.) with your ERP (for example, NetSuite). And to connect those systems as seamlessly as possible, experienced teams and integration consultants use special middleware (or connectors) – the best example of which is Celigo.

The Benefits of Supply Chain Optimization

On the most basic level, optimizing supply chain management with Celigo’s help brings about three major benefits:

Increased Efficiency

Celigo automates repetitive tasks, which frees up your team to focus on more important, strategic initiatives. You will also gain real-time insights into your inventory, shipments, and supplier status – this will help you make swift and informed decisions, making you very agile.

Additionally, you can easily avoid overstocking and stockouts with a more optimized supply chain, which means ever optimal inventory levels.

Cost Reduction

There are multiple ways in which Celigo helps to cut down on your expenses – the most obvious one is through the aforementioned automation that reduces the need for manual labor and allows you to reallocate resources to more critical areas. Moreover, Celigo helps plan the most efficient shipping routes, reducing fuel consumption and transportation costs.

Maintaining just-in-time inventory levels also reduces storage costs – Celigo ensures precise inventory management, preventing excess stock. And with deep insights into purchasing patterns, you can negotiate better terms with suppliers – for instance, volume discounts and improved credit terms.

Improved Customer Satisfaction

An optimized supply chain also means consistent on-time delivery, which, in turn, builds trust and loyalty with your customers. On top of that, effective inventory management ensures that popular products are always in stock, preventing missed sales opportunities and improving the customer experience even more.

Key Features of Supply Chain Optimization

Amongst the very wide range of new features associated with optimization in supply chain, we’ve chosen to focus on the following seven, which we deem the most important:

Inventory Management

- Dynamic Inventory Replenishment: With Celigo’s integration, you can set dynamic replenishment rules based on real-time data. This ensures that inventory levels are continuously adjusted according to your sales patterns.

- Multi-Location Inventory Tracking: You can seamlessly manage inventory across multiple locations, which helps with the optimal distribution of stock and reduces the risk of localized shortages or overstocking.

- Batch and Expiry Management: Effective inventory management includes tracking batch numbers and expiration dates. This is crucial for industries like pharmaceuticals and food, where product shelf life directly impacts quality and compliance.

Demand Forecasting

- Predictive Analytics: You will be able to better predict future demand – this involves analyzing historical data, market trends, and seasonal variations to create reliable demand forecasts.

- AI and Machine Learning: Incorporating AI and machine learning models will help refine forecasting accuracy even more as these models learn from data patterns and improve over time.

- Scenario Planning: You can run multiple forecasting scenarios to prepare for various market conditions. This helps in developing contingency plans and maintaining your supply chain resilience.

Process Automation

- Automated Order Processing: You can automate your order processing tasks, from order entry to fulfillment. This reduces manual intervention, accelerates order cycles, and minimizes errors.

- Automated Compliance Checks: Ensuring regulatory compliance can also be automated – you can check orders and shipments against compliance requirements in real time.

- Workflow Automation: Also possible is the automation of complex workflows involving multiple systems and stakeholders, enabling your processes to be executed very efficiently.

Data Integration

- Unified Data Platform: You can integrate data from various sources into a single platform, getting a 360-degree view of your supply chain.

- Real-Time Data Sync: You can have your data synchronized in real time across all systems, which is crucial for maintaining operational efficiency and responsiveness.

- Customizable Dashboards and Reports: You can also create custom dashboards and reports, which helps to get more targeted insights and allows for more effective monitoring of your supply chain performance.

Supplier Coordination

- Collaborative Planning: You can improve the way you make plans with your suppliers, ensuring that your production schedules and inventory levels are aligned with your demand forecasts.

- Supplier Performance Tracking: Tracking supplier performance will allow you to monitor metrics such as delivery times, quality, and compliance.

Logistics Optimization

- Route Optimization: Using more advanced algorithms, you can optimize your delivery routes to minimize travel time and costs.

- Freight Management: Optimization will also allow for more effective management of freight, including carrier selection and load optimization, which reduces transportation costs.

- Cross-Docking: You can implement cross-docking strategies to streamline the transfer of goods from suppliers to customers, bypassing warehousing stages and reducing storage costs.

Performance Monitoring

- KPI Tracking: You will be able to track all of your crucial KPIs – order fulfillment rates, lead times, inventory turnover and many others.

- Real-Time Alerts and Notifications: Setting up real-time alerts for critical events (e.g., delays, stockouts) will help you minimize critical disruptions.

- Continuous Improvement: You will get all the tools for your continuous improvement – more accurate data will help you refine your processes and improve your supply chain performance.

Common Optimization Problems in Supply Chain Management

Supply chain management can have many more weak spots than the two described in this section. However, after working with hundreds of clients, we feel the need to specifically highlight the trouble of manual work and no real-time visibility:

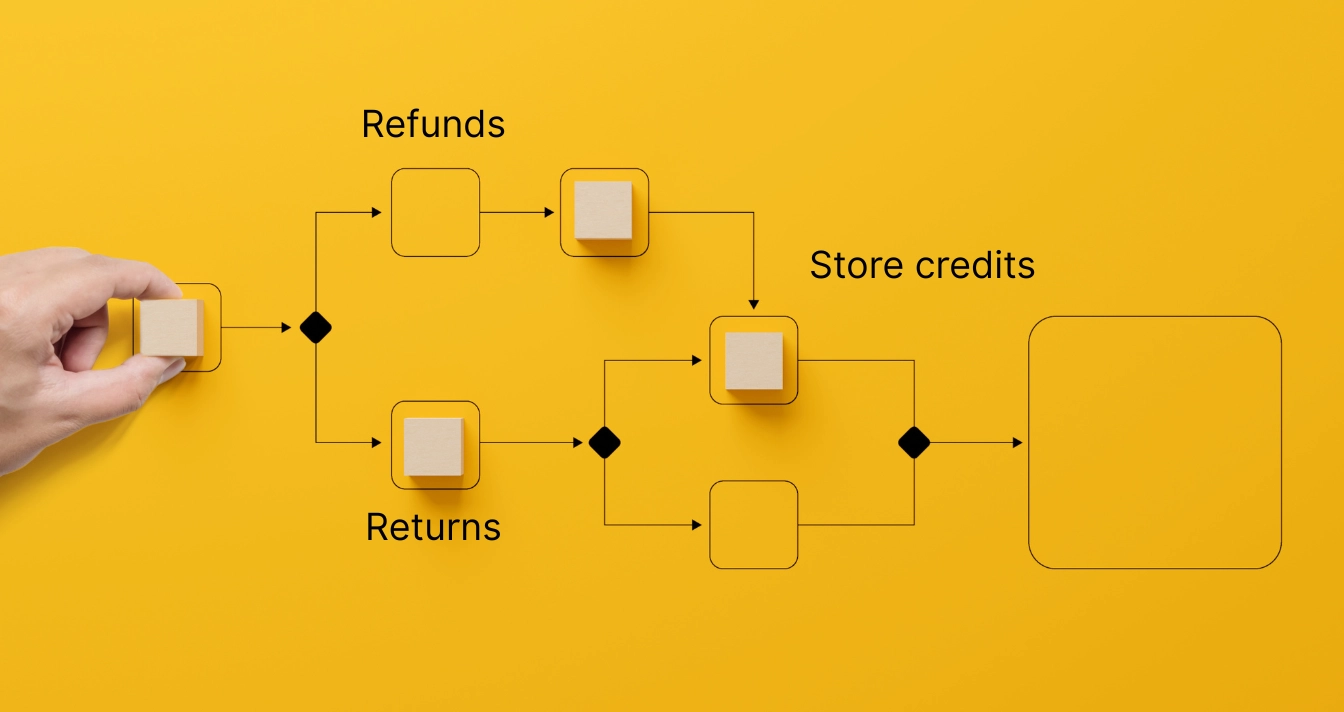

Manual Processes

Manual processes often involve repetitive tasks like data entry, order processing, and inventory updates. These tasks are not only time-consuming but also prone to human error, which can lead to significant operational inefficiencies and delays. This way, manually entering order details into multiple systems can cause delays, especially during peak times, and increase the chances of mistakes.

To make matters worse, as a business grows, manual processes become increasingly unmanageable. The more transactions and data points that need to be handled, the higher the likelihood of errors and bottlenecks. Not to mention, manual work often requires a larger workforce, leading to higher labor costs.

Lack of Real-Time Visibility

Without real-time visibility into inventory levels, shipments, and production status, decision-making is often based on outdated information. If a company can’t see real-time inventory levels, it may over-order or under-order stock, leading to either excess inventory or stockouts.

Moreover, real-time visibility is crucial for effective coordination with suppliers. Without it, suppliers may not be aware of changing demand patterns, leading to mismatched supply and demand. So if a supplier is not updated in real-time about a spike in demand for a particular product, they may not be able to ramp up production quickly enough, leading, once again, to delays and stockouts.

Celigo’s Tools for Streamlining Supply Chain Processes

As a logical response to above supply chain optimization problems, a clever integration of Celigo can offer the following capabilities:

Integration Solutions

Celigo’s integration platform connects disparate systems across the supply chain, making sure that all your departments operate with the same information. For instance, apart from the natural e-commerce to ERP connection, you can also integrate CRM, and WMS systems that will allow seamless data flow, improving your decision-making.

On top of that, Celigo offers pre-built connectors for popular ERP systems like NetSuite, along with e-commerce platforms, logistics providers, and other key systems. These connectors facilitate quick and efficient integration without the need for extensive custom coding. This, in turn, accelerates deployment times and reduces the complexity typically associated with system integrations.

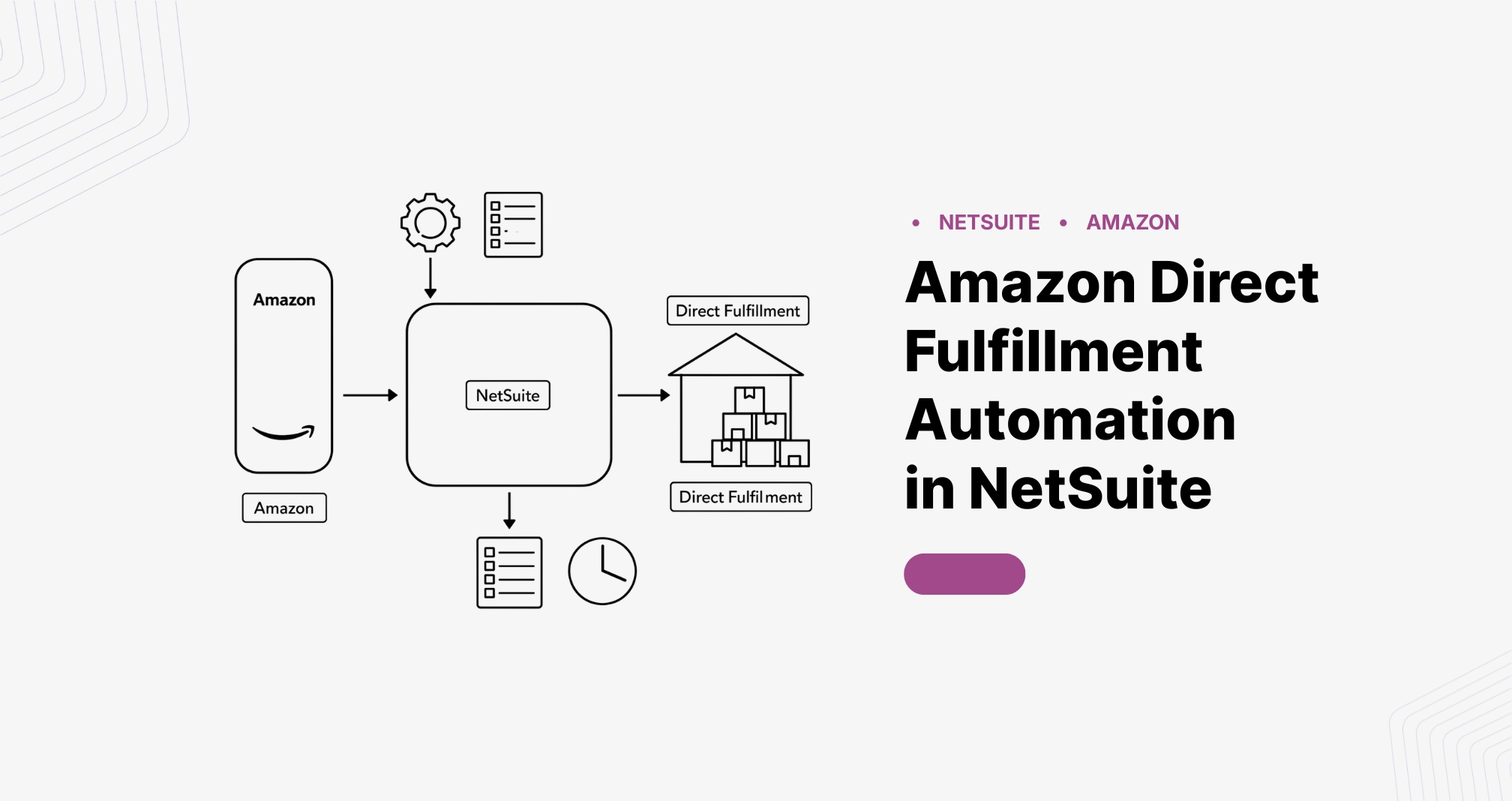

Automation

Celigo supports the automation of end-to-end supply chain processes, from order processing to fulfillment and shipping. For instance, you can automate the order-to-cash process to ensure that orders are processed, fulfilled, and invoiced efficiently, reducing the order cycle time.

Celigo can also automate alerts and notifications for various critical events such as low inventory levels, delayed shipments, or compliance issues. This will allow you to promptly address critical issues – automated alerts for low inventory levels can trigger reordering processes, preventing stockouts and ensuring continuous product availability.

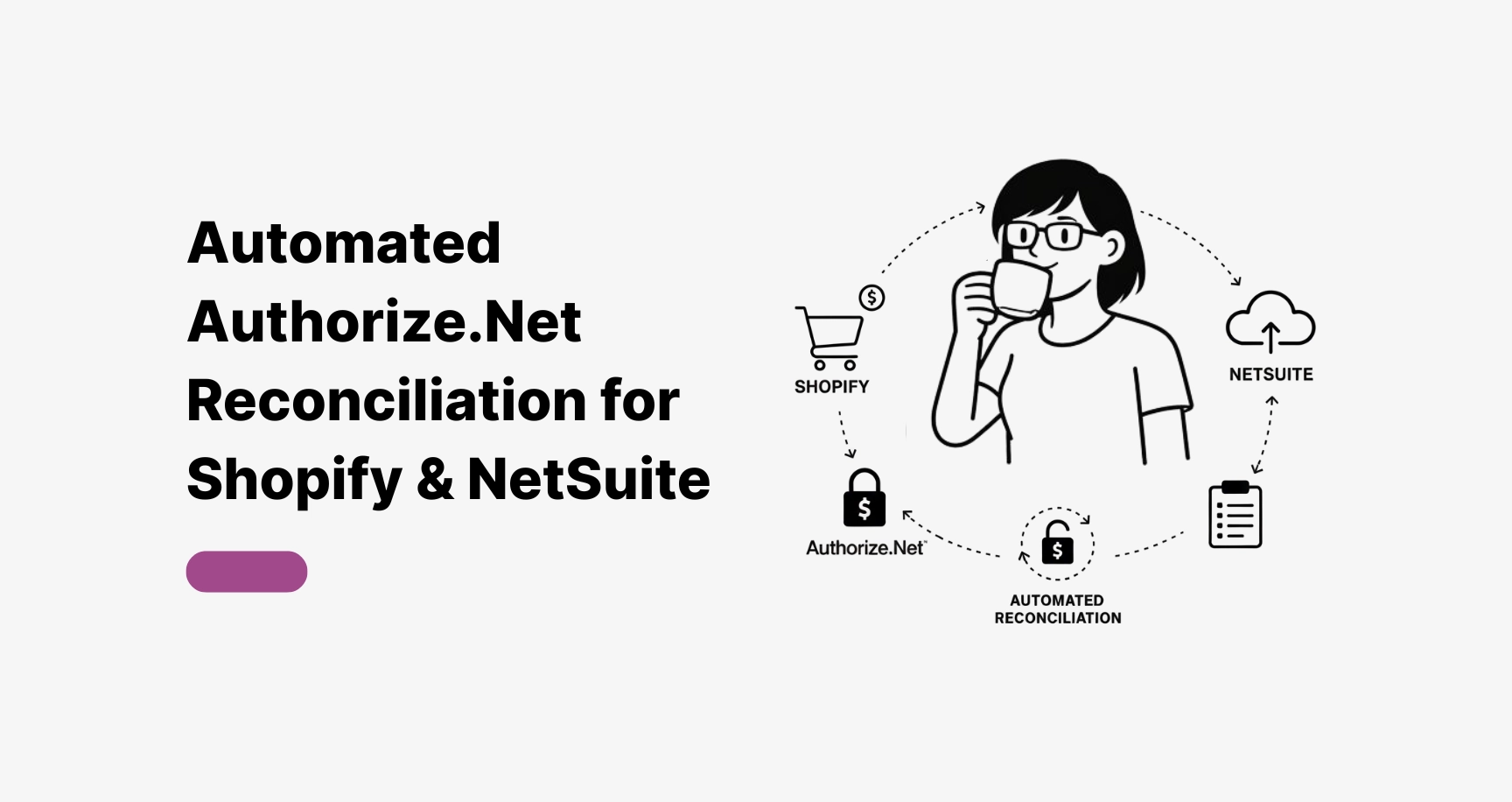

Real-Time Data Sync

The system ensures that data is synchronized in real time across all integrated systems – this means that inventory levels, order statuses, and customer information are always up-to-date. And with real-time data sync, you can gain greater visibility into your operations, for instance, better tracking of shipments, monitoring of production processes, and management of inventory.

Additionally, the sync helps you achieve data consistency, which reduces discrepancies and errors. For example, consistent data across your CRM and ERP systems will ensure that customer interactions and sales records will be accurately reflected in your financial reports.

How Celigo Supports a Comprehensive Supply Chain Optimization Plan

On top of day-to-day process improvements, let’s take a look at how a Celigo EDI integration is capable of boosting your e-commerce business long-term:

Strategic Planning

Celigo’s platform helps you develop robust long-term supply chain strategies. Using its advanced predictive analytics, you can forecast demand more accurately than ever before. It will also allow you to model various supply chain scenarios and simulate their potential impacts. This helps in assessing risks, identifying opportunities, and planning for contingencies.

Scalability

Celigo’s modular approach to integration will enable you to scale your supply chain operations very smoothly. As you grow, additional integrations can be easily added without disrupting existing workflows.

Moreover, Celigo supports elastic scalability, which means the platform can handle increased data volumes and transaction loads without performance degradation. This is particularly important during peak seasons or promotional events when order volumes spike.

Support and Training

Lastly, Celigo offers great onboarding services – detailed setup assistance, system configuration, and initial training sessions. They provide extensive training resources, including webinars, tutorials, and certification programs, to help your team maximize the platform’s potential.

At the same time, continuous support from Celigo’s team ensures that you can resolve issues promptly and keep your supply chain operations running smoothly. This includes 24/7 technical support, regular system updates, and access to a vast knowledge base.

Conclusion

A solid supply chain optimization plan is critical for e-commerce businesses striving to stay competitive – and integrations with Celigo are must-haves of such a plan. Celigo is a transformative tool that connects vital systems and provides a robust framework for enhancing your efficiency.

It helps automate repetitive tasks, facilitates real-time insights and allows for seamless expansion and adaptation to increased data volumes and transaction loads, among many other benefits.

However, an effective use of Celigo requires thorough preparation, and a well-structured process – something that not all teams can handle on their own. That’s why, should you experience any problems before, during or after the Celigo integration process, don’t hesitate to reach out to a team of professionals like Hairball – we will get the job done.