Managing orders manually can seem straightforward at first, but as you grow, the complexity and risk associated with manual processes can become overwhelming. Here’s a closer look at some of the key challenges that come with handling NetSuite order management manually.

One of the biggest risks in manual order management is the potential for human error. Entering incorrect customer information or miscalculating totals can lead to serious consequences – most importantly, frustrated customers.

Every step from entering order details, checking inventory, processing payments, to updating records needs individual attention. What’s worse, the bigger you become, the more time is needed to manage each order, which can lead to various delays.

To continue the topic of growing – as you expand your operations, the limitations of manual order management become more apparent. Scaling up while relying on manual processes is difficult because it often involves hiring more staff to handle the increased workload. In turn, this tends to increase labor costs and introduce even more opportunities for errors.

Manual NetSuite order management often leads to communication breakdowns, especially when multiple departments or teams are involved. For example, the sales team might take an order without checking inventory levels, or the warehouse team might not be immediately aware of an urgent order that needs to be prioritized.

Keeping track of orders and generating reports manually needs a lot of attention to detail and constant updates to make sure that all records are accurate. This can make it difficult to identify critical trends or spot certain issues in a timely manner.

Ultimately, all of the challenges mentioned above, from errors to inflexibility, will lead to customer dissatisfaction. Customers expect quick, accurate, and transparent service – and when you fail to meet those, you will see lost sales, negative reviews, and damage to your brand’s reputation.

Automated order processing is the practice of using software to handle the various stages of an order’s lifecycle without requiring human intervention at each step. This system takes over the repetitive, time-consuming tasks that are typically involved in processing orders.

Now let’s break down how it works and why it matters.

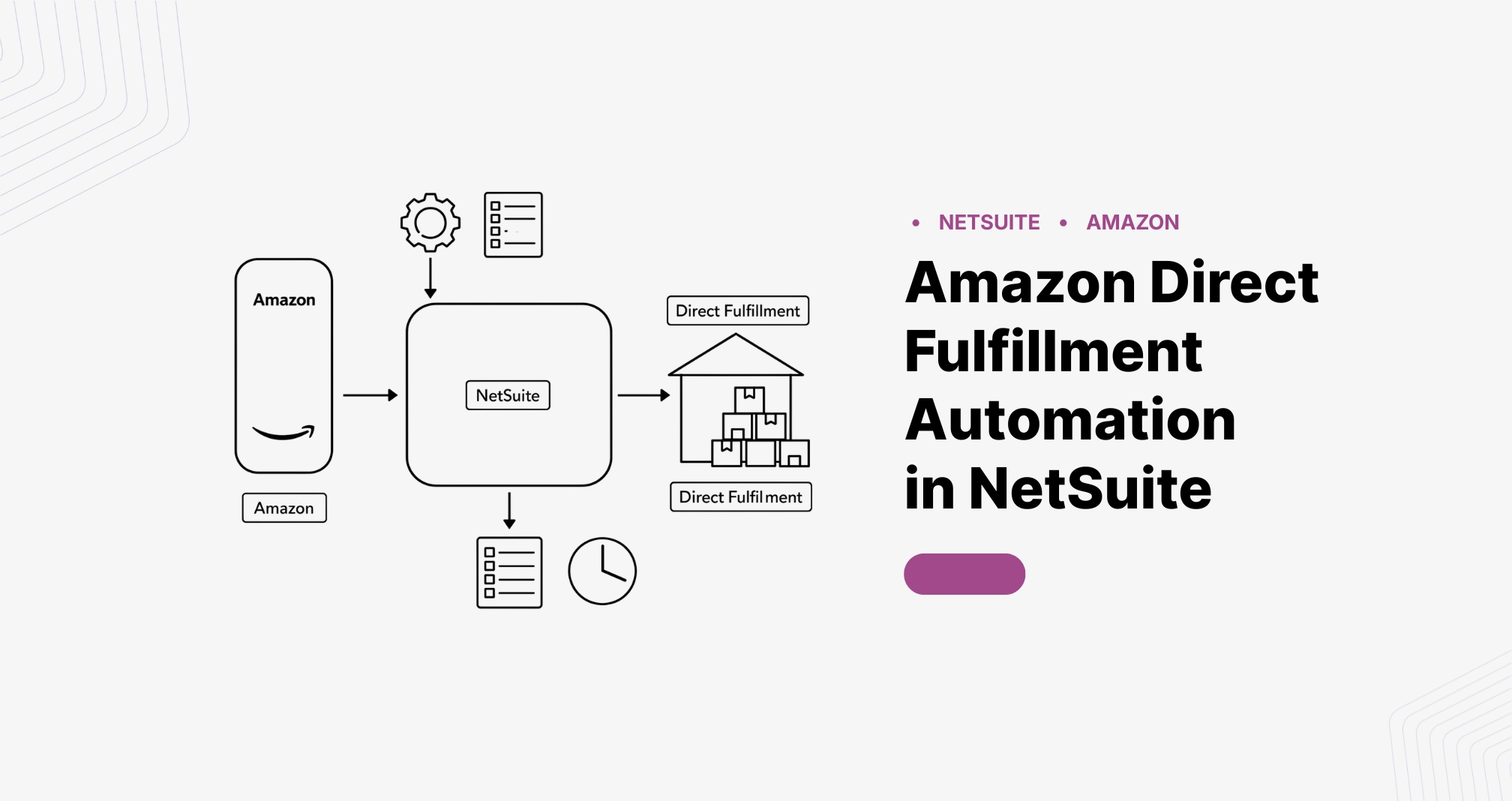

In a manual system, someone would need to input the order details into a system, but automation removes this step. The software directly captures the order information from the e-commerce platform or point-of-sale system and inputs it into the order management system (OMS) automatically.

Sales order processing automation also helps with inventory management – when an order is placed, the system can automatically check the availability of the products. If stock levels are low, it can trigger reorders or adjust availability on your sales platform.

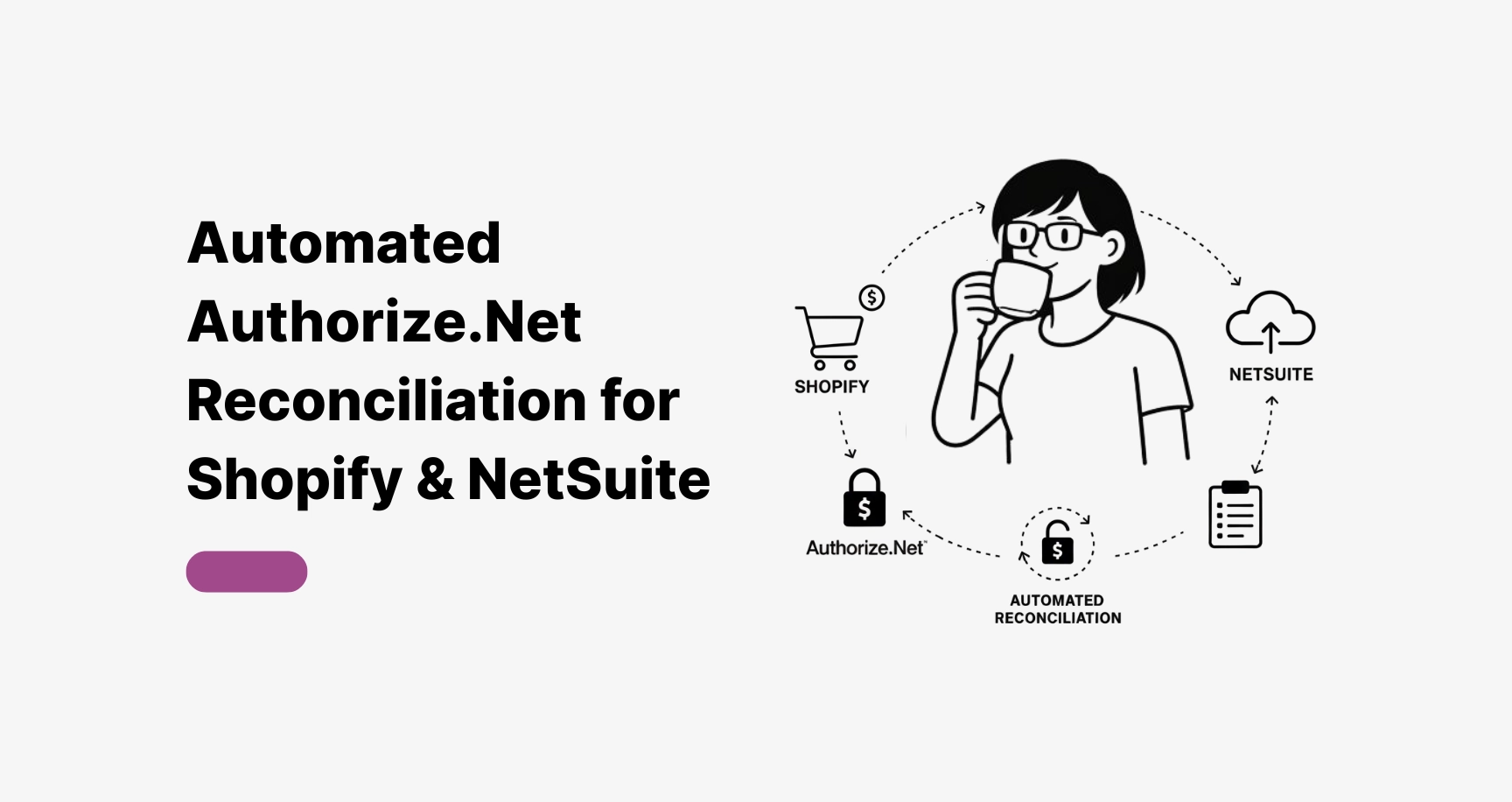

Automated systems can easily handle payments by securely processing credit card information – the software ensures that all transactions are verified and that funds are captured before moving on to the next stage. And if there are issues (insufficient funds or payment errors) the system can flag these immediately.

Automated order processing systems also handle order routing, deciding where to send the order for fulfillment based on factors like inventory levels, shipping costs, and proximity to the customer. For instance, if you have warehouses on the East and West Coasts, the system can automatically route orders to the warehouse closest to the customer.

On top of that, the automation system takes care of shipping and delivery coordination. It selects the best carrier based on cost, delivery time, and customer preference, generates shipping labels, and tracks your packages in real-time.

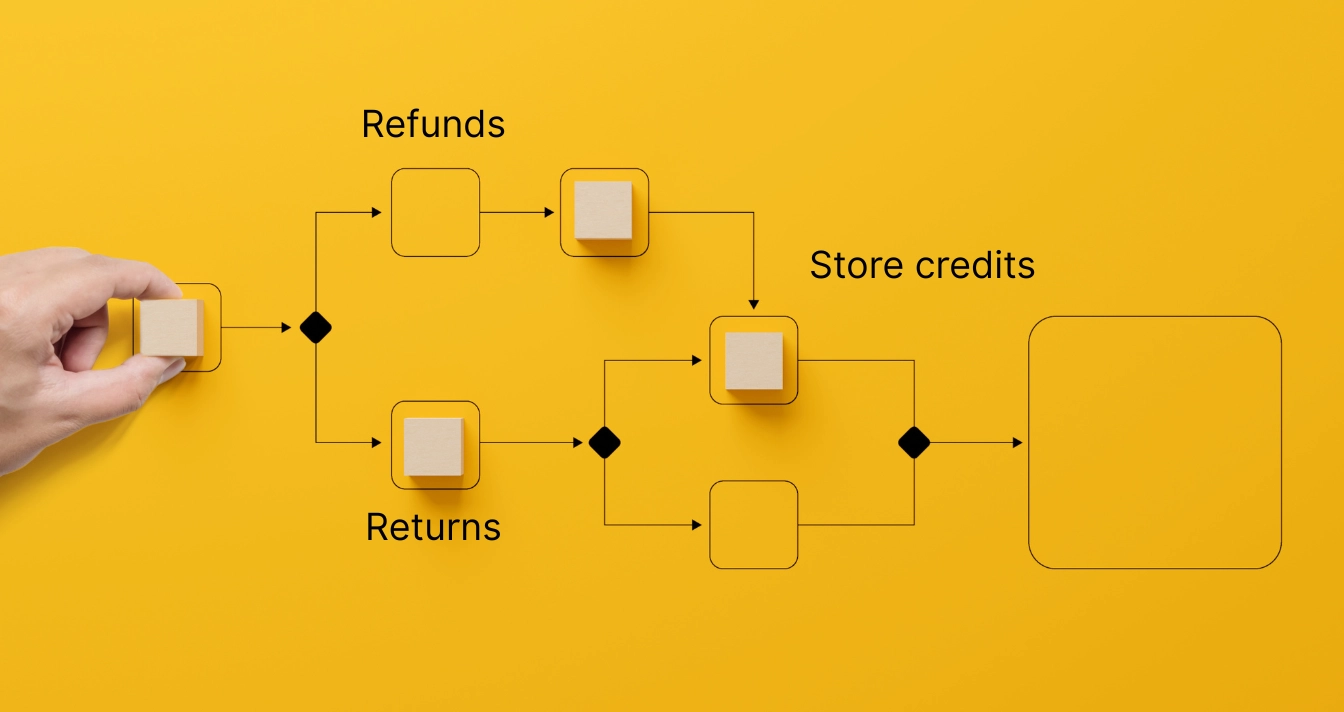

Finally, automation also extends to post-sale activities – for example, when a return is initiated, the system updates the stock, processes the refund, and can even trigger an email to the customer confirming the return. This reduces the workload on customer service teams and makes sure that customers are promptly taken care of.

Integrating Celigo with your order management system offers several unique advantages that only Celigo can bring, namely:

Celigo also provides all the flexibility you need to set up the exact automation rules that reflect your specific order processing needs. You can create conditional workflows that handle different types of orders differently, such as prioritizing express shipping orders or automatically flagging high-value orders for additional review.

When issues arise (and they inevitably do), the system can automatically detect and flag them, be it a failed payment or a discrepancy in inventory levels. Celigo then sends alerts to the relevant teams or individuals, which helps you avoid delays that could impact customer satisfaction and your revenue.

The platform allows you to track key metrics across your order management system, providing insights into your performance – for instance, you could monitor the average time taken to fulfill orders and identify the most common causes of delays.

So instead of relying on guesswork or manual reporting, you get real-time insights that help you refine your operations and become as efficient as ever.

Celigo is also designed to handle large amounts of data and manage multiple integrations simultaneously, making it ideal for businesses experiencing rapid growth or seasonal spikes in demand. During a peak season, the system can automatically adjust to handle the increased order volume without much manual intervention.

Last but definitely not least, you can significantly reduce labor costs associated with manual data entry, order processing, and error correction. Employees who were once tied up with these tasks could focus more on high-value activities, which not only saves money but also improves your productivity.

Additionally, the accuracy of automated processes reduces the risk of costly mistakes like inventory mismanagement, which contributes to cost savings even more.

Automation can only work as well as the data it processes – make sure to remove duplicates and standardize all formats (like addresses and customer names). You should also run regular audits of your customer database and inventory records before and after implementing automation to catch any discrepancies early.

You can create highly specific workflows in NetSuite, but, for them to work, it’s crucial to set clear rules about which orders follow which paths. For instance, regular orders might go through an automated approval process, while bulk orders or those over a certain dollar amount might require manual review.

That’s why you need to define and document these workflows in detail, specifying conditions that trigger different processes – this documentation will help in troubleshooting and training staff.

Automation can handle routine orders with ease, but there are also edge cases, which can be massively disruptive. You need to test how your NetSuite automation handles unusual or complex scenarios, such as international shipping, custom orders, or orders with special discounts.

Create test cases for these scenarios and run them through the system to see how they are handled. After that, adjust your workflows based on the results to avoid potential issues when these cases arise in real life.

One of the biggest headaches in NetSuite order management is keeping your inventory levels accurate, especially when you sell across more than one channel. NetSuite allows you to automate inventory updates, but it’s important to fine-tune this process so that it accurately reflects real-time stock levels.

You should set up alerts that automatically trigger purchase orders or transfer requests when inventory falls below a certain threshold – and make sure they are based on realistic lead times and sales velocity to avoid both stockouts and overstock situations.

In the end, no automation is foolproof – whether it’s a failed payment, a system outage, or a misrouted order, your system should have predefined responses to handle such errors. That’s why you should see scripts or custom workflows to automatically flag and reroute orders – if a payment fails, the order could be moved to a “Pending Review” queue where it’s either retried or flagged.